What is NMR Spectroscopy?

Organic compounds emit certain frequencies of light when surrounded with high intensity magnetic fields. The devices that produce the magnetic fields and read the resulting emitted light from the compounds are called Nuclear Magnetic Resonance Spectrometers. High-end machines can run to frequencies of greater than 200 MHz. To do this, these highly-tuned instruments require superconducting magnets, cryogenic cooling, lots of space, and big budgets. Typically the preserve of universities and well-funded research organizations, they are out of the financial reach of an ordinary industry lab and impractical to implement in multiple locations or near other equipment. |

"As a Startup, they needed an affordable way of starting production without breaking the bank; we got them started and ramped up without any production tooling."

Jean-Sebastien Langlois - Project Lead

|

The golden-goodness of good-enough

With the arrival of super-strong, rare-earth permanent magnets, Nanalysis could create a viable desktop-sized machine. The bright insight of the team at Nanalysis was envisioning a less powerful 60MHz machine that could cover the vast majority of daily tasks in industrial labs. A machine that would be good enough. One that could be made with rare-earth magnets. No more need for tanks of liquid nitrogen to cool superconducting magnets.

|

|

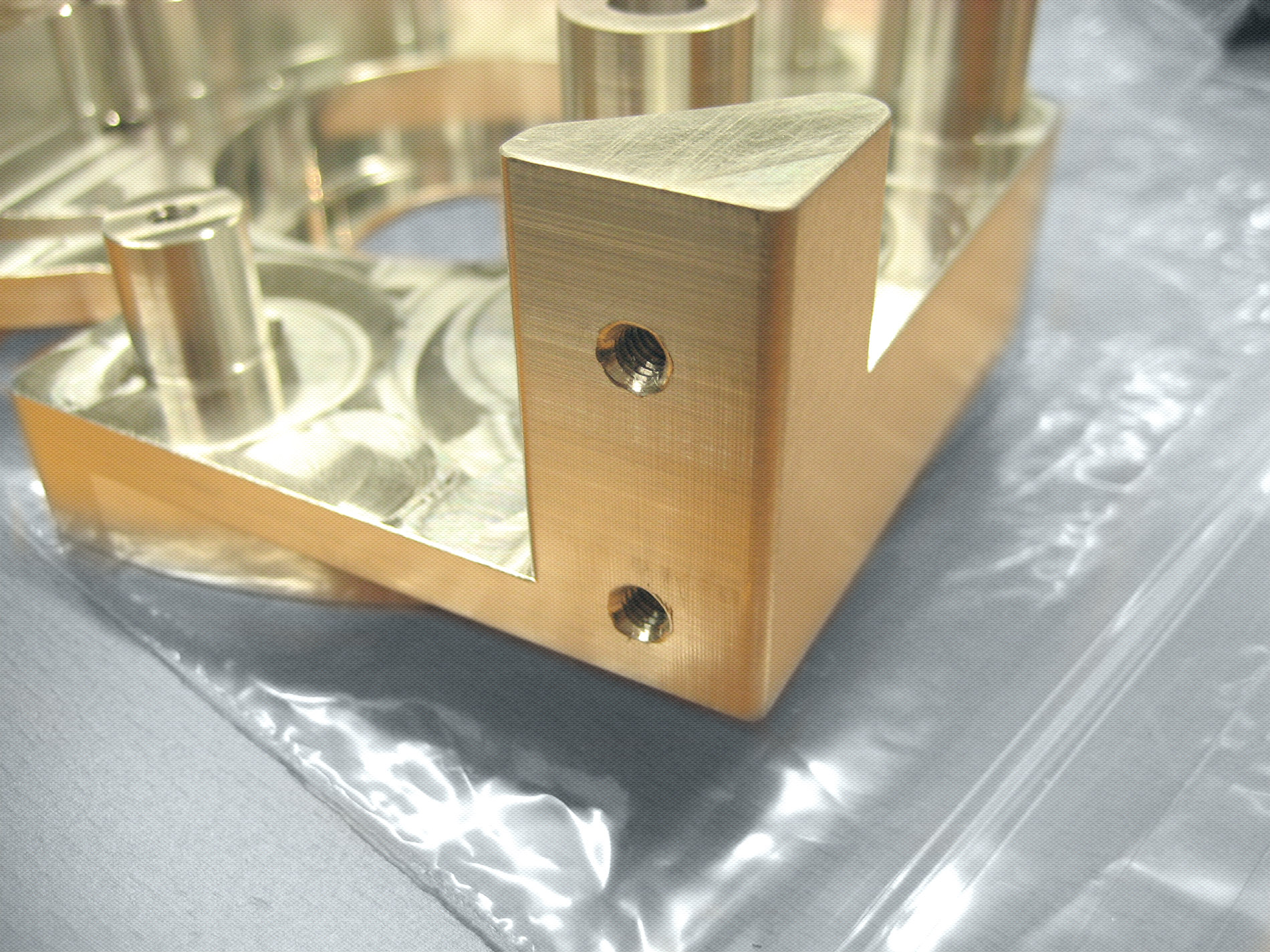

Orchestrating a symphony of vendors and parts

Many design shops stop once the drawings are done and the prototypes admired. Not Advanta. For Nanalysis, we rolled up our sleeves and ran through our Rolodex to source the right vendor to fabricate each part. Advanta coordinated the fabrication of all of the parts to create batches of production lots. Each time parts came in, they were reviewed for any required modifications. Changes were noted and the documentation updated to reflect the update as Nanalysis and Advanta together strove to optimize and perfect the design.

|

"When they need something, it gets started immediately. I guess we are an extension of their team...on demand!"

Vincent Hamelin - Product Designer

|

Multiplying Advanta expertise

Nanalysis, like all our clients, are experts in their technological fields of endeavor. Advanta designers are experts at creating optimal design and production solutions to enclose, embrace, and present that technology to the world. Combining the two creates exciting and profitable products. At the start of our engagement, Nanalysis had a basic layout of all the components and machine functioning. Advanta absorbed this information and worked with it to create a compelling solution.

Ergonomic analysis

Quick testing to determine the best screen viewing angle for both taller and shorter technicians who may be either standing or sitting in front of the machine.

Branding and reviewing other high-end equipment

What does a "lab device" look like anyway? What other products on the market look high-end, and which cues should be incorporated into the product to achieve a unique high-value look for Nanalysis? These studies became one of the foundations for creative exploration and concept development.

Get to 3D quickly

For each concept presented to Nanalysis, a volume model was made from foam to give them an idea of the size. Once a concept was selected, a preliminary weighted volume model was produced to test handling – the magnets alone weigh 40lbs, so we needed to ensure anyone moving the device could hold onto it!

Getting the details right

For the final design, Advanta developed and modeled each and every component in 3D CAD. From the sheet steel enclosure to every last nut and screw, Advanta produced complete project documentation, including a detailed BOM (Bill of Materials) integrated into the computer models and automatically generated by the software.

|